Filtration

n., plural: filtrations

[fɪlˈtɹeɪʃən]

Definition: the act or process of filtering

Table of Contents

Filtration Definition

What is filtration? Filtration is separating a solid from a fluid through a porous material that holds the solid and fluid passes through. It is important to note that the fluid includes both liquids and gases. The filter may be chemical, biological, or physical.

Filtration is the process of separating suspended particles from the fluid through a porous material in which the fluid can pass while the suspended particles are retained. It refers to the process of segregating solids from the fluid (liquid or a gas) by passing it through a filtering device. Related term: ultrafiltration

Filtration is a biological process where water and solutes move across the cell membrane due to hydrostatic pressure from the cardiovascular system. Example: renal (ultra)filtration, a process in which the blood is filtered in the glomerulus of the kidney so that substances (e.g. cells and proteins) that are essential can be retained and selectively reabsorbed by the body.

Filtration Process

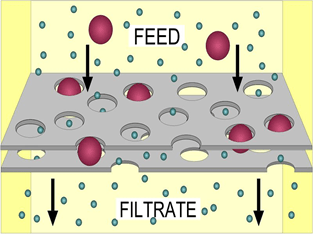

In the filtration process, a heterogeneous mixture is dispensed over a filter membrane. The filter membrane or the filter medium has pores of a specific size. The particles with size and dimension larger than the pores of the membrane cannot pass through the membrane and are retained over the filter membrane.

At the same time, particles of smaller size will pass through the membrane pores along with the fluid. The oversized particles will get deposited as a residue over the filter membrane, and liquid will pass through the filter membrane. Thus, separating the solids and fluid from the heterogeneous mixture. The suspension of the solid and liquid to be filtered is known as the slurry.

The porous medium used to retain the solids is known as filter medium. The accumulation of solids on the filter is the filter cake. The clear liquid obtained through the filter is the filtrate. A most simple example to understand this can be seen during tea making. We filter out prepared tea from the tea leaves using a sieve. The tea, along with dissolved sugar, will easily pass through the pores of the sieve, while tea leaves would be retained over the sieve. Removal of dust particles from the air in the air conditioner is another example of filtration.

Based on this understanding, the parts of a primary assembly of filtration systems are:

- Filter medium

- Slurry (or the fluid with suspended solids)

- Filteration driving force (e.g., pressure, gravity, etc.)

- Filtration device that holds the filter medium and filtrate along with the application of driving force.

Components of the filtration process

Let us briefly understand all the components required for the filtration process.

- Filter medium

Ideally, the filter medium must be strong, have a low resistance to the fluid flow, and remain unaffected by the substances present in the slurry. Materials that are used as filter media includes-

Woven materials such as felts or cloths in wool, cotton, silk, glass, metals, or synthetic fibers (rayon, nylon, etc.). The filtration cloth may vary in weight and weave. The weave of fabric will affect the surface and strength of the filtration cloth.

Perforated sheet metal is also used as the filter medium. Beads of granular solids built upon a supporting medium are also used as filter mediums, for example, gravel, sand, asbestos, paper pulp, kieselguhr. The solids may vary in size according to the process requirement. In some instances, a bed of graded solids may also be used as the filter medium to reduce the resistance to fluid flow through the bed.

Similarly, certain porous solids like sintered glass, sintered metal, earthenware, and porous plastic, e.g., Porvic) etc., are also used as a filtration medium.

The selection of filter material will depend upon the type of slurry, chemical composition, and purpose of the filtration process. - Slurry

The filtration process is affected by the characteristics of the slurry as follows:- The properties of the liquid such as density, viscosity, and corrosiveness

- The properties of the solids- particle size, particle size distribution, and the rigidity or the compressibility of the solid.

- The proportion of the solids in the slurry.

Additionally, the objective of the filtration process is to collect liquid or solid; whether the solids have to be washed frees from the liquid also influences the whole filtration process, selection of filtration method, and rate of the filtration.

- Filtration driving force

The filtration rate is proportionate to the pressure difference across filter medium and filter cake. The pressure drop or pressure difference can be achieved in several ways, which includes:

Gravity: This is the simplest method of obtaining pressure difference is by maintaining the head of the slurry above the filter medium. The pressure difference created is due to the liquid gravity pull. Herein, the pressure difference generated will depend upon the density of the slurry.

Low pressure: The pressure below the filter medium may be reduced below the atmospheric pressure by applying a vacuum pump in the filtrate receiver, resulting in a pressure differential across the filter. However, in this method, the pressure difference is limited to 1 bar since it can not exceed the pressure exerted by the atmosphere on the surface of the slurry. Also, reducing pressure lowers the boiling point of the liquids, so there are chances that filtrate may start boiling in the receiver. Despite this limitation, this method of achieving pressure drop is the safest and widely used filtration approach.

High pressure: Applying pressure to the surface of the slurry is also a widely used method for filtration. However, this method achieves a higher pressure difference than is obtainable with reduced pressure.

Centrifugal force: Centrifugal force is used to provide the driving force for the filtration process. Centrifugation is based on the principle that an object that is rotated about a center point at a constant radial distance is acted upon a force known as centrifugal force. This creates a pressure difference and aids in the filtration process.

Functions of Filtration

Filtration can be a physical process or a biological process. The physical application of filtration can be seen routinely all around our daily life—purification of water to remove impurities, coffee filters, automotive filters, belt filters during mining, etc. Filteration is also a sterilization technique that filters out the microbes out of the product without applying heat.

On the other hand, an example of filtration occurs in the kidney, and kidneys are biological filters that filter out the toxins out of the body and retain the essential nutrients in the body. Here we can conclude that the filtration process occurs biologically as well.

What is filtration medical definition? Filtration is the removal or filtering of the toxins and waste products from the blood by the kidney. They are excreted from the body through urine. In general, filtration refers to the passing of a liquid through a filter. In the human body, the kidney functions as a filter.

So, anatomically and physiologically, filtration is a process wherein waste and toxins are removed from the body through glomerulus filtration, which results in urine production. Where does this filtration occur? The filtration occurs in the kidney, particularly, in the renal corpuscle. Biologically, cell filtration occurs passively through the epithelial membrane, wherein cells flush the undesirable substance out of the cell.

Types of filtration

Let’s find out the different types of filtration below.

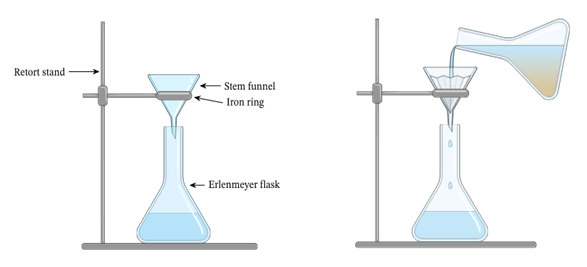

Gravity filtration

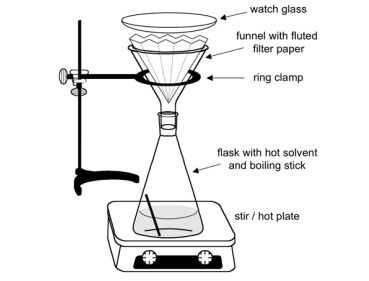

Gravity filtration is the simplest form of filtration technique wherein the driving force for the filtration is the gravitational force. Filtration under gravitational force is the most commonly used filtration technique. In this method, filter paper is placed in a funnel that has been fixed on an iron clamp. The liquid is then poured over the filter paper. Due to gravitational force, the liquid travels in a downward direction.

Thus, it gets collected in the beaker placed below the funnel as filtrate. At the same time, the residue gets deposited over the filter paper. See figure below.

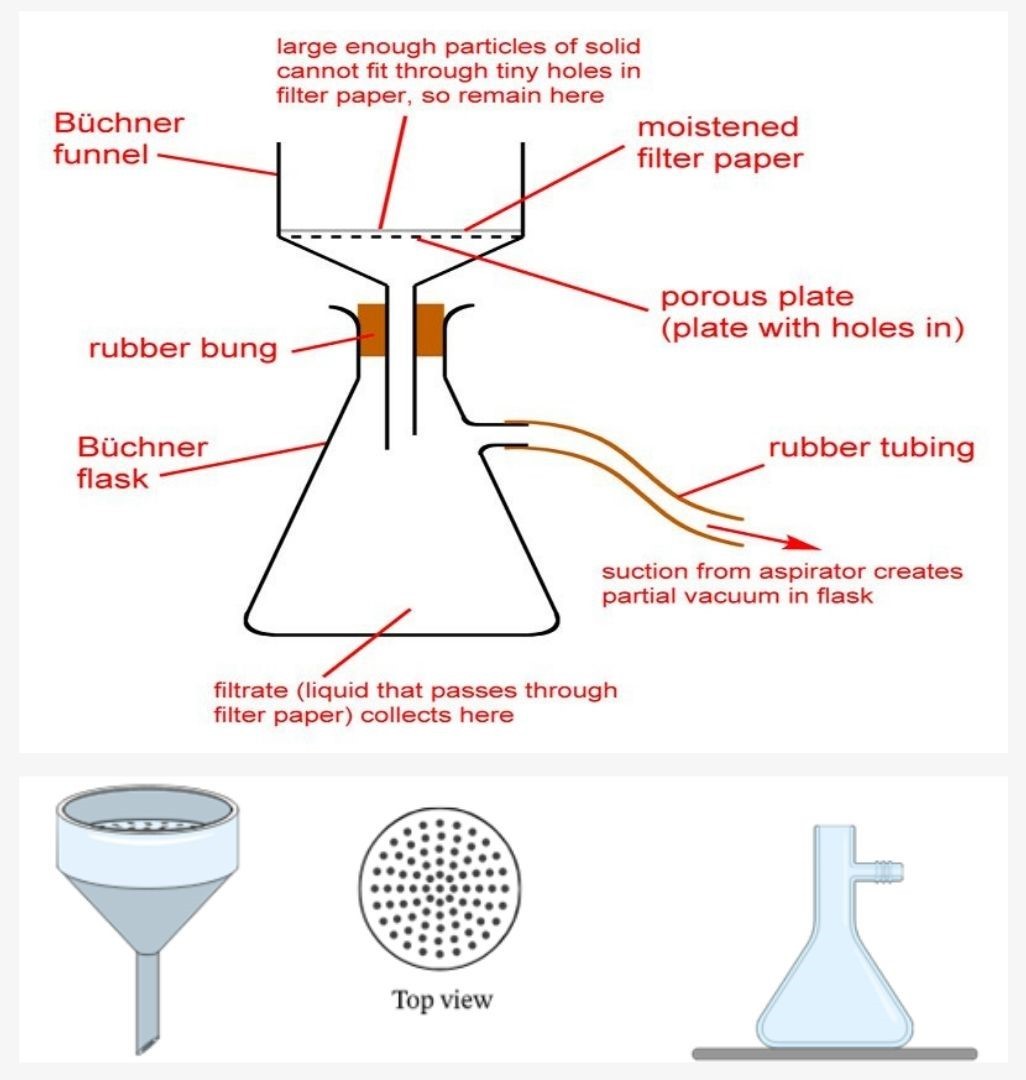

Vacuum filtration

Vacuum filtration is quite similar to gravity filtration. In vacuum filtration, the liquid passes through a filter paper placed in a funnel. However, the filtration driving force is the applied vacuum. Therefore, the application of vacuum makes this a faster process in comparison to gravity filtration.

Vacuum filtration setup consists of a Buchner flask and funnel and a vacuum pump to create a vacuum. Buchner’ flask is used for carrying out vacuum filtration. The Buchner’ flask is connected to a vacuum, which forces the liquid to pass through the filter paper into the flask when turned’ ON’.

Centrifugal filtration

Centrifugal filtration utilizes centrifugal force as the driving force for the filtration process. Centrifugal force is the inertial force experienced by an object moving in a circular path. Centrifugal force pushes the material outward or away from the centre of the rotation when it is moving in a circular orbit.

The instrument consists of a rotating drum through which the slurry is passed. Due to centrifugal force, the liquid is pushed out of the drum while the filtrate is retained on the walls of the drum.

Hot Filtration

The hot filtration method is used for the liquid that tends to crystallize rapidly. Crystals grow rapidly in such cases and block the filtration assembly. For such cases, the temperature of the liquids is raised to avoid crystal formation. Therefore, the whole filtration process is carried out rapidly and at high temperatures to reduce crystal formation.

Stemless filter funnel and Fluted filter papers are required to carry out the hot filtration. Hot filtration carried under the gravitational driving force is referred to as hot gravity filtration. It is generally carried out in an Erlenmeyer flask, filter paper, a stemless funnel, and a hot plate (see Figure 4). The purpose of hot gravity filtration is to remove insoluble impurities from a hot solution.

Cold Filtration

This process is opposite to cold filtration, and crystallization is desirable. Widely used in the beer industry, the protein clump formation is initiated by lowering the temperature and eventually separating the crystals from the remaining liquid.

Multilayer Filtration

Water purification is an example of multilayer filtration wherein water is passed through different layers of filters (sand, gravel, or charcoal etc.) to remove impurities. The filtering water passes through different medium layers. Depending on the particle size, impurities are filtered out at each stage of the filtration. Filtration through additional layers of filters increases the filtration efficiency and ensures clean water.

Filtration Examples

We depend upon the filtration process in our daily lives; some of the common examples are as follows:

- Water purification methods to remove impurities from it. Depending on the final water usage, different filters are used to eliminate contaminants from the water. Potable water for home usage, i.e., purification drinking water, is generally carried out through granular-activated carbon filters, metallic alloy filters, depth filters, carbon block resin filters, and microporous ceramic filters, along with ultrafiltration and microfiltration membranes.

- HEPA (high-efficiency particulate air) filters are frequently used for air purification to eliminate harmful allergens, bacteria, and pollutants. Air is filtered through a mesh of different pore sizes, anti-microbial layer panels, and ultraviolet light panels that remove particulate matter, bacteria, and allergens. HEPA filters are 99.9% efficient in air purification. These filters are also present in vacuum cleaners.

- Automotive filters, such as Air Filter, Cabin Filter, Fuel Filter, and Oil Filter, are some of the automotive filters that remove particulate matter from fuel & air and increase the vehicle’s longevity.

- Aquarium filters are a combination of three types of filtration, i.e., mechanical filtration, biological filtration, and chemical filtration. Mechanical filters act on the principle of size and remove large impurities. Gravel, sponges or foam are the mechanical filters. Biological filters are useful bacteria that convert harmful ammonia and nitrite to harmless nitrate compounds. Finally, chemical filters in an aquarium are activated charcoal or carbon that adsorb harmful chemicals from the water. Combining these three types of filters helps maintain the aquarium environment clean and conducive for aquatic life.

- Gas filters have separate filters for different types of gases. Accordingly, a gas filter attached to a gas generator or purifier will have a dedicated filter for different gases. For example, the air purifier will have separate filters for oxygen and carbon dioxide. Air is a mixture containing oxygen, carbon dioxide, and pollutants. So, purified air will have at least two filters that will vent out the purified oxygen. At the same time, the other will be oxygen not included gas filter to separate the vent the carbon dioxide and pollutants from purified air.

- Belt filters in mining, apple cider vinegar making, and in the wine industry

- Tea and coffee filters

- Reverse osmosis

- Dialysis. Kidneys are the biological filters that filter out the toxins from the body with urine and retain & reabsorb the essential nutrients by glomerular filtration. However, when kidneys malfunction or stop functioning, filtration out of toxins from the body stops. This can lead to the accumulation of these toxins in the body, which can be fatal. Hence, for the removal of these toxins, dialysis becomes essential. During dialysis, body fluid is passed through a semipermeable membrane with varying pore size, which results in filtration and elimination of the unwanted material from the body fluid. Essentially, dialysis acts like artificial kidneys and helps in the removal of toxins from the body.

Try to answer the quiz below to check what you have learned so far about filtration.

References

- Coté R. J. (2001). Sterilization and filtration. Current protocols in cell biology, Chapter 1. https://doi.org/10.1002/0471143030.cb0104s01

- Coté R. J. (2001). Sterilization and filtration. Current protocols in cell biology, Chapter 1. https://doi.org/10.1002/0471143030.cb0104s01

- Levy, R. V., & Jornitz, M. W. (2006). Types of filtration. Advances in biochemical engineering/biotechnology, 98, 1–26. https://doi.org/10.1007/b104242

- Reif O. W. (2006). Microfiltration membranes: characteristics and manufacturing. Advances in biochemical engineering/biotechnology, 98, 73–103. https://doi.org/10.1007/b104245

©BiologyOnline.com. Content provided and moderated by Biology Online Editors.